In the course of the evolution of management, and especially the evolution of scientific management, the production management branch was introduced several decades ago as a way to systematize in-plant operations. This approach has been coupled with a systematic approach in an efficient and effective manner so that managers in the field of production can recognize components effective in processes and operations and solve the production and even service issues with a comprehensive view. Today, with the increasing competitiveness of the market, the basic constraints such as reducing the time to market the product and minimizing the time to advance the production of the product in the production process, the need for feedback or information flow and the implementation of reform in production also organizations to integrate operations produced. With the use of industrial automation in the production management system, a mechanism is created to assist in the integration of processes and production operations of all requirements and constraints, and are automatically executed and all commands are also operational at the very least in the shortest possible time.

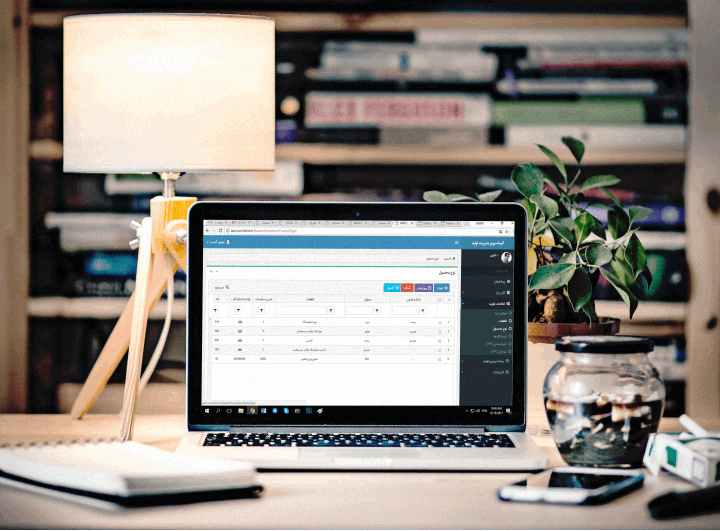

Integrated Production Management Portal Dadekavan

Solution introduction

- Manage order-based production routines

- Registration of complete formulation and production process (OPC)

- Ability to define the components needed to build each product

- Separating workstations with a dedicated carton for each user

- Complete process of quality control with the possibility of recording performance of semi-finished products and products

- It is possible to record the performance of production including healthy produce, waste, mismatch and duplication

- Provide a report of a semi-fabricated inventory in the manufacturing process, broken down by work stations

Solution features

Description

Dade kavan’s Management Automation is a place for industrial management within a production complex. This automation involves different roles for access to different parts of the system. Each role can have at least one user. The system administrator is surrounded by the entire collection and has full access to all menus. The system administrator defines an OPC routine. Each step in the OPC includes a workstation; it also has a similar workstation in two OPC steps. Each role can be assigned to one or more workstations. The workstation consists of a set of activities to be performed by the respective role. If there is a similar workstation in place at the OPC several steps, it is possible to separate the activities of that station between several steps.

Possibilities

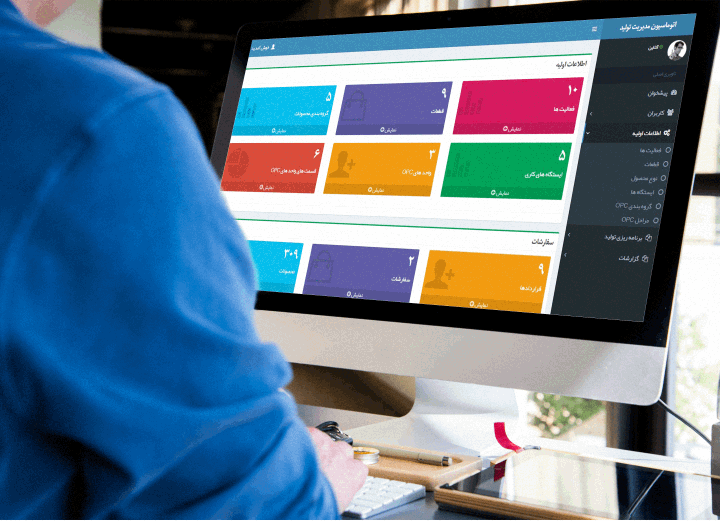

Total automation facilities

- Dashboard management

- Project Management

- Manage roles

- Manage users

- Reports

- Products

- Settings

Extensibility

- The design of the website is such that it can be expanded and expanded to produce the app. Also, with the Modular Oriented standard, adding the modules desired by the employer to the project will be possible. All of the infrastructure is written as a service and can be developed for a variety of operating systems (IOS / android / windows ...).

Reports

- Ability to produce a variety of reports with the ability to print, store, share on social networks and...

- Reporting based on different fields for each of the opts, projects, roles, users and products individually.

- Provide periodic reports related to production and process progress

Manage users

- Administrator and administrator can delete or record user. There will also be categories for editing.Ability to categorize and group products

- It is possible to view each user's information, such as role, name, and contact number and ... by management.

- It is possible to record all user activity by role.

Facilities Management Projects

- The system administrator in this section can create OPC for all processes.

- The system is designed to allow OPCs in the database to be read through a separate service.

- The possibility of assigning sub-levels and branches to various roles by admin will be possible.

- The administrator's access to a project's routine is possible and the current status of each project is possible.

- If there is a problem in each project section, the manager can view the problem through the recorded reports and follow the 0relevant section.

- nage client files and documents

Features of dashboard management department

- It has an easy-to-use routine that speeds up user affairs.

- Executive requirements related to the tasks of each user will be visible on the panel.

- The design of the entire department is in such a way as to provide easy access to the user.